Unser Leitbild

Unsere Kunden sollen durch unser Flüssigkeiten-Management die Möglichkeit erhalten, ihre Ressourcen ökonomisch sinnvoll und voll automatisiert und digitalisiert einzusetzen, so dass sie sich ganz und gar ihrem eigenen Handeln widmen können. Damit streben wir nach einem angemessenen wirtschaftlichen Erfolg für unser Unternehmen, um ihn für die Werte und Bildung unserer Mitarbeiter einzusetzen und die Zukunft unserer Gesellschaft durch stetige Innovationen zu sichern.

VON DER EINZELKOMPONENTE BIS ZUR INDIVIDUELLEN PROZESSLÖSUNG

Technische Beratung // Herstellung // Verteilzentrum // Außendienst // After-Sales Service

Zu Hause in verschiedensten Branchen

Wir versprechen nicht. Wir garantieren.

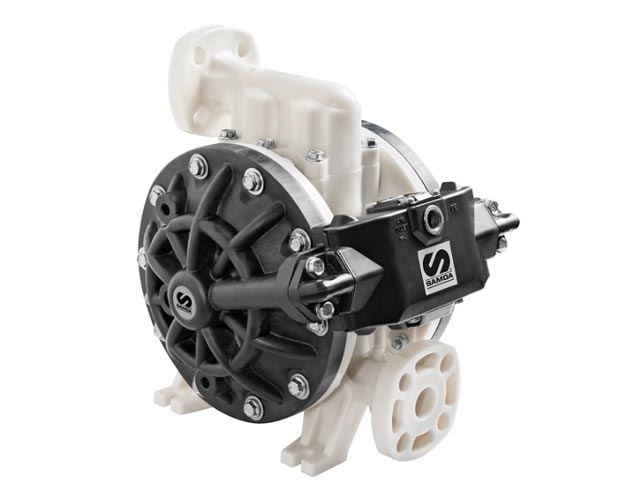

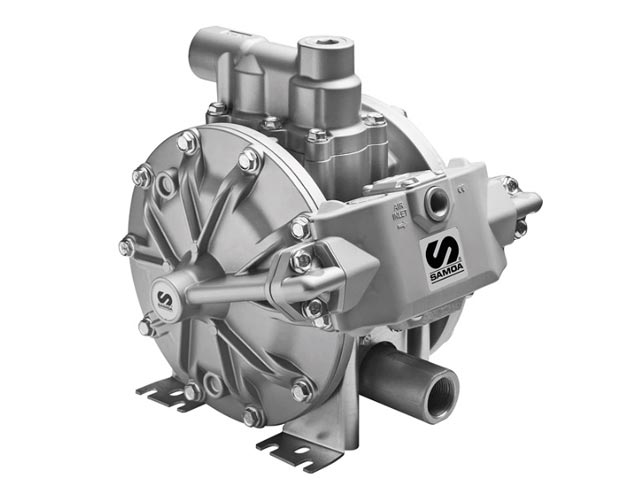

SAMOA PRODUKTE & SYSTEMANWENDUNGEN

WELTWEIT IM EINSATZ

Mehr als 40 Jahre Erfahrung deutscher Ingenieurskunst im Maschinenbau und dem Handling unterschiedlichster Flüssigkeiten industrieller Anwendungen, erlauben uns für Sie die optimale Auswahl der Produkte & Komponenten aus eigener Produktion zu treffen, ob nun zur Einzelverwendung oder im Verbund innerhalb einer automatisierten Prozesslösung.